Many thanks to Trebor for this suggestion

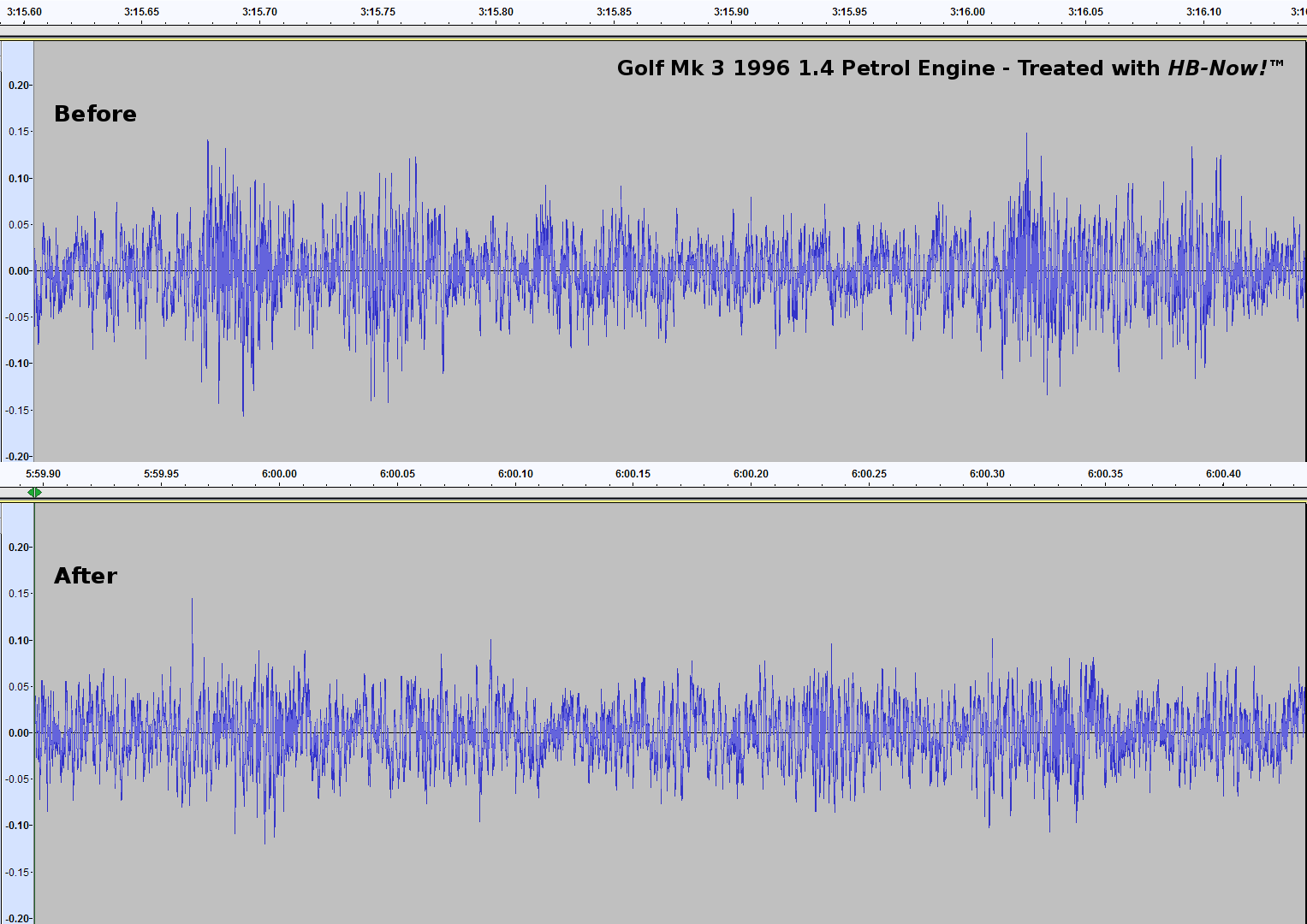

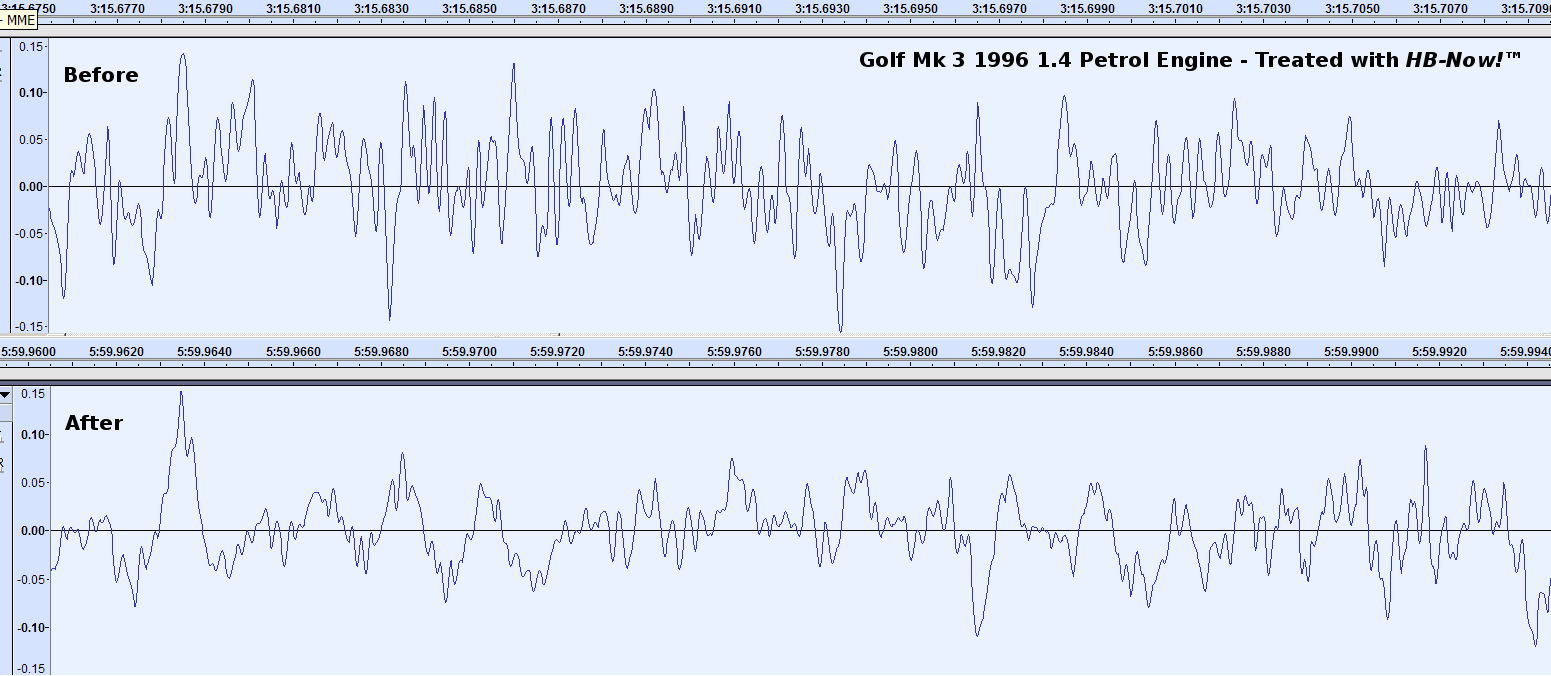

SPAN plus Spectrum Analysis hb-now-golf-mk3_transition_mono.wav

Method

The first and last second of the audio file were graphed in SPAN plus using default settings.

Each graph was exported to image.pgn then imported to GIMP.

Alpha channels were added.

Chart background removed.

The chart foreground of ‘the last second’ was replaced with a transparent colour, to enable overlay.

Note:

‘SPAN plus’ was chosen, over ‘Plot Spectrum’ as the latter dB axis could not be locked.

This prevented comparative overlay.

Analysis Concept

By overlaying the ‘after audio’ over the ‘before audio’ … a form of analysis might present itself.

Analysis

Preamble

A piston engine creates noise due to components rubbing or knocking together, displacing air/gas, and explosions.

A worn lubricated bearing might produce a low frequency rumble.

An unlubricated bearing might produce a very high pitch squeal.

A large worn reciprocating component might produce a low pitch knock.

A small reciprocating component might produce a mid to high pitch knock.

Certain components, such as ‘valve actuation’ involve direct impact of metal upon metal, potentially mid to high pitch knock.

However, it is worth noting that, unlike earlier pushrod ‘tappet valve actuation’

… the overhead camshaft impacts the valve with a glancing blow, followed by rubbing.

Clearly, some noises are independent of lubrication, but a large proportion can be ameliorated by lubrication, or improved lubrication.

… particularly worn engines, where component interfaces are larger than when the engine was new.

These larger interfaces can be filled with larger lubricating oil molecules (effectively larger ball bearings).

This route may be worth pursuing - it is sound engineering practice (hence differing grades of oil).

However, some components may have worn less, and may still require ‘thinner oil’ (so be careful - small increment change is wise).

Also the thicker oil may be more problematic when beginning circulation in cold temperatures (at engine start).

In modern engines, almost all component rubbing or knocking, is a function of rotation

Increased lubricity (of the oil) will ameliorate engine lubrication in all situations (where sufficient oil pressure is being maintained).

Hexagonal Boron Nitride particles provide this increased lubricity.

This molecule is stable under pressure, and when dispersed in the oil, presents an ever-present lubricant between metal surfaces (particularly useful at engine start).

By adding this molecule to the oil, in a worn engine, we would expect to witness a reduction in noise that is being produced as a function of rotation.

Can engine noise be eliminated - or does it change it’s form?

A well designed bearing may make no discernible noise, when adequately lubricated.

Therefore, we can expect that, after HBN introduction, some noise might effectively disappear.

However, for a worn engine, the prediction would likely be, that the original component noise will drop in pitch (with improved lubrication).

Ie. Noise will still be created, but it will be dampened, like hitting a bell via a piece of leather.

Therefore, we would expect a downwards shift in frequency.

In chart terms … a leftward shift in the ‘volume’ of noise/frequency instances.

… with a corresponding increase in lower frequency sounds.

Let’s have a look:

Note:

I’m going to use the term ‘volume’ to describe the quantity of noise under a given section of the curve of the graph.

This may correspond to the traditional sense of audio volume … or not.

Confirmation of this, or better terminology is required.

8.3K - 20K

Better than a 50% reduction in high frequency sound - sharp rubbing and knocking.

This is very good news for engine wear and efficiency.

However, those engine components are still producing noise, but the improved lubrication means that the noise is of a lower pitch.

Therefore we can expect that noise to show up in the volume of lower pitched noise.

1.7K - 8.3K

We can see a distinctive half wave curve, from 1.7K to the cliff edge of 8.3K (nature is mind-blowing).

While there is a reduction in the ‘volume’ of noise in this pitch band

… it is not great, and we can see that at some odd pitches, there is greater volume than prior to HBN treatment.

From this, we need to make an ‘informed guess’.

Ergo … that most of the original component impacts were reduced in intensity, but that reduced volume now, is augmented by the component noise that previously was in the higher pitch region.

The 4.6K region is encapsulated in yellow bias.

The 4K region is encapsulated in blue bias.

Clearly, there is a notable component impact, that has settled in the 4.6K region - slightly more than was originally present.

… unlike per-chance in the 4K region

This is a very positive sign.

Increased lubricity cannot increase the impact noise pitch.

Therefore, this is confirmation that ‘component on component impact’ has been reduced, with the resulting noise pitch being relocated at a lower level.

Nice!

180 - 1.7K

Let’s disregard the anomaly of 180 - 240 (apparently a happy place for noise).

Instead, we can go with the flow of nature, and see the half wave curve from 180 - 1.7K.

There are two or three minor areas showing an increase, but we now understand this.

… overall, there is a significant reduction in the volume of noise in this ‘pitch region’.

… far more than in the previous 1.7K - 8.3K region.

Where has the noise gone, from that previous region?

I believe that we must think deeper.

Those highest pitched tapping/screeching noises were reduced to the 1.7K - 8.3K region

… but those components have a limited noise generation capability.

They can reduce down from natures highest pitch, to the second highest pitch

… but thereafter, it would seem that the second highest pitch cannot transition to the 3rd highest pitch region.

They probably don’t have the mass, and the additional lubricity simply ‘keeps them in their place - rotating nicely’.

In effect (as witnessed) … a proportion of the component impacts are eliminated (because they don’t add to the 3rd highest pitch region).

… and we still have significantly reduced component impacts, that create noise in the 180 - 1.7K region.

… but those impacts still occur.

Will we see an increase in the lowest pitched noise?

32 - 180

Once again, we see nature at play.

For whatever reason, the impact noises (due to additional lubricity) find their home in two distinct regions.

Alan Turin (when he was killed/committed suicide) was researching nature’s fundamental requirement to form patterns.

… we see it here.

Summary

Taken at a common sense level

… what we see, is easy to understand.

The additional lubricity reduces impacts/rubbing, causing the noise to drop in pitch.

The components creating the highest pitch noise, are the components that can be easier supported by the additional lubricity

… therefore they no longer make noise.

Apparently, this impact noise reduction, forms into two general patterns (in overview).

However, it is also apparent that the noise is finally reduced to a level that is not recognised by the microphone, or the analysis software.

Neither of these latter two provisos impact upon our general understanding

… that is:

Hexagonal Boron Nitride particles provide increased lubricity, and is beneficial, in terms of reduced engine friction

… ‘noise’ being a primary indicator.

Ha!

… and by strange (and rare) good fortune … I have loads of the stuff

How annoying will that be (to the few)?

…

![]()